As I’ve documented in previous

posts, HMS Terror’s stern well was to be filled with strengthening chocks

when the propeller wasn't in use. A unique feature of this design was described

by Oliver Lang, the shipwright in charge of the 1845 refit, as an “iron tank

placed over the chocks in which any small article of stores may be stored” (NMM

ZAZ5683 [J1529]). Lang’s 1845

plan, while vague, suggests that the tank was similar to iron storage tanks

used in Royal Navy ships of the era, with one major difference: the fore and

aft faces of the tank had two grooves running along their length to seat it on

the rails in the propeller well (see my previous post).

|

| Oliver Lang's 1845 design for the storage tank (right). National Maritime Museum, Greenwich, London (ZAZ5683 [J1529]). |

Iron tanks had been used in the Royal Navy since 1813 and were used to store all manner of dry and wet goods, and were often used as ballast tanks when stores were depleted or offloaded (Pearson 1992). An example of the types of tanks used in the Franklin era can still be found in the excellently preserved Dealy Island Storehouse, constructed by Captain Kellett of HMS Resolute. The storage tanks were iron, ca. 48 inches by 48 inches in size, with lines of rivets along the middle and alternate edges of each face and around their circular openings (Jane 1982: Figure 3, Figure 6). I copied this rivet pattern in my reconstruction of the Terror’s stern tank.

The openings of these tanks were sealed with a recessed cast iron lid, between 12 and 24 inches in diameter with a wire rod handle and a cork or wooden bung inserted into a circular opening in their centre (Pearson 1992:24). Maudslay, Sons, and Field, who were contracted to supply the engines installed in HMS Erebus and Terror (Battersby and Carney 2011:201), owned the patent to produce ship's tanks (Pearson 1992:25), and it is reasonable to assume that they built the custom stern tanks for the Franklin Expedition. If so, the "Maudslay, Sons, and Field" name should be stamped on the cast iron lids for the tanks, if they are ever found (e.g. Pearson 1992:26).

As can be

seen above, the profile dimensions of the Terror’s stern tank are shown on Lang’s

plan, as well as a general indication of the size and position of the lid and

two iron rings used to raise and lower the tank into position. The plans

indicate the tank had the following profile dimensions:

Height = 40 inches

Length (moulded) = 25 and ½

inches

I have

estimated, based on the distance between the stern frames, that the propeller

well and the tank were sided approximately 34 inches.

References:

Pearson,

Michael

1992 From Ship to the Bush: Ship Tanks in

Australia. Australasian Historical Archaeology 10: 24-29.

Janes, Robert R.

1982 The

Preservation and Ethnohistory of a Frozen Historic Site in the Canadian Arctic.

Arctic 35(3):358-385.

Battersby, William, and Carney, Peter

2011 Equipping HM Ships

Erebus and Terror, 1845. International

Journal for the History of Engineering and Technology 81(2):192-211.

|

| Sheet brass scored prior to cutting. |

|

| A pounce wheel was used to mark the location of the rivets. |

|

| The rivets were simulated by punching the brass from the reverse side with the sharp end of a file. |

|

| The central opening and wire handle of the lid were made from brass tube and wire. |

|

| The outer rim of the lid was soldered into place. The central opening (right) was trimmed and soldered to a plate to form the bottom of the lid (wire still needs to be trimmed to length). |

|

| The completed lid soldered in place and cleaned up (sanding is still required and the central hole needs to be drilled to remove the wire rod). |

|

| Rings for raising and lowering the tank soldered in place. |

|

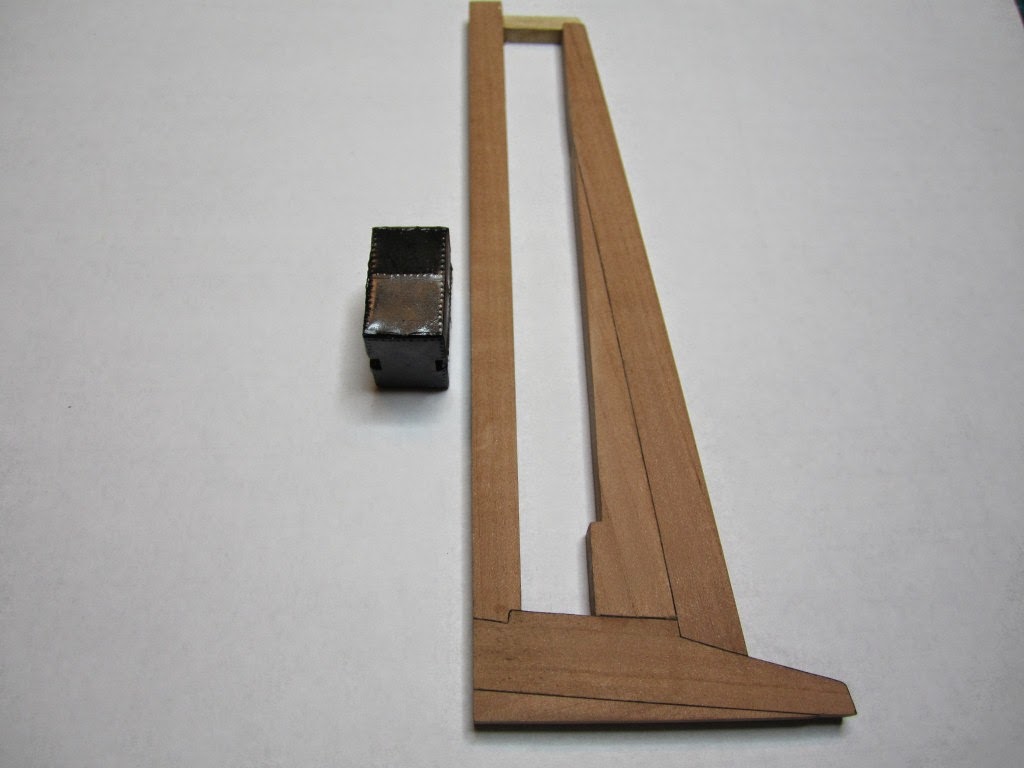

| The tank parts after chemical blackening. The grooves were made from existing brass stock. |

|

| Soldering the entire tank was impossible, so a balsa form was created to glue the plates in place. |

|

| Starboard side glued in place. |

|

| Detail of the top of the tank. The bung in the lid was made with wood-filler. |

|

| The approximate position where the tank will sit in the well. I'm waiting for the oil to fully penetrate before I dry-fit the piece to the wood. |

|

| A crude model of Captain Crozier provides a sense of scale. |

Fantastic work.

ReplyDeleteRegards

Thomas

Thank you Thomas!

ReplyDeleteImpressive - well done!

ReplyDeleteFantastic work! I love how intricate the work is for these smaller-scale models. If the ship is already small, the tank has to be even smaller. The work would be very delicate, indeed. What else are you trying to do with the Terror? Keep us posted!

ReplyDeleteBrandi Bradley @ Rotax Metals

Thank you so much for this wonderful blog.

ReplyDelete