There are few secret places left to be explored in the world; but there

is one waiting under the waters of Terror Bay.

The announcement that HMS Terror was recently found "in pristine condition" is

astonishing, yet the revelation that the ship's stern lights (stern cabin

windows) have survived intact is especially poignant. Behind those 171-year-old stern lights is the very definition

of a secret space; the cabin where Captain Crozier received reports and

dispatched orders; where he entertained Franklin, Fitzjames and his officers in

the better days; and where he huddled over his charts, plotting and planning

his men’s desperate escape from the ice.

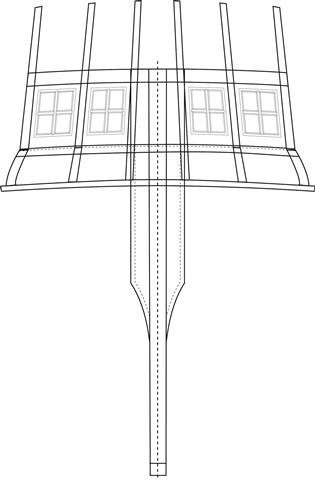

By 1845, Terror’s stern

windows were very different from those Captain John Sheridan gazed through as

he bombarded Baltimore in 1814. In 1812, Henry Peake designed a relatively

traditional stern gallery for HMS Terror,

which included seven stern lights in addition to six windows arranged on her port

and starboard quarter galleries. Each of the stern windows had nine panes,

while the smaller quarter gallery windows had six panes.

|

| Henry Peake's original 1812 design for Terror's stern gallery and quarter galleries. NMM, ZAZ5662 |

When Terror was first converted

for polar service over 1835 and 1836, its vulnerable quarter galleries (and the

water closets they contained) were removed, resulting in a reduction to five

stern windows. Contemporary artwork by Owen Stanley indicates that the windows

retained their original nine-pane configuration during Back's harrowing Arctic expedition

of 1836-1837.

|

| Terror's stern lights in 1837. Note the cipher and ship's name depicted above the hanging rudder. NMM, PAF0275 |

Since the time of Parry’s second Arctic voyage, 24 years previously,

polar exploration vessels had been fitted with "double window-frames"

(1), and Terror undoubtedly had

double windows installed for Back’s 1836 -1837 Arctic voyage. Parry described

that during the coldest months, "cork shutters" were inserted between

the sashes on HMS Hecla (1), and it

is possible that cork shutters were used on Terror’s subsequent polar voyages.

Contemporary images suggest that Terror's

stern gallery remained unchanged during the Antarctic expedition of 1839-1843,

when Terror was under the command of

Francis R.M. Crozier, although the 1839 Terror

and Erebus plans indicate that significant changes were made to the great cabin itself.

In the spring of 1845, Terror

and Erebus had their sterns

dismantled and reconstructed to accommodate large wells needed to raise and

lower their new screw propellers. The centre window on the stern of each vessel

was removed to make room for the new well. Green-ink annotations on Terror’s 1836 plans show that her stern

frames were shifted slightly forward during the 1845 refit. The reasons for

such an extensive refit are unclear, but it may have been necessary to redesign

the stern framing to accommodate the weight and stress of the new

propeller system.

While it appears that the remaining four stern windows were kept (roughly) in their original positions in 1845, the windows themselves were

redesigned from a nine-pane to a four-pane configuration. We know this because

of a remarkable woodcut of the great cabin of HMS Erebus, which appeared in the May

24th, 1845 issue of the Illustrated London News (2). The accompanying

article described that the windows were “double[d]”, similar to those used on

Parry’s voyages. Astonishingly, high resolution images of the cabin

illustration in the report clearly show the double sashes.

| The Great Cabin of HMS Erebus, as depicted in a woodcut from the May 24th, 1845 edition of the Illustrated London News |

Why the stern lights were modified to a four-pane design is unknown, but

the woodcut indicates that by 1845 the window muntins were much more robust

than those on a typical stern window. A sturdier design might have been thought necessary, after the unprecedented heavy seas and storms Terror and Erebus encountered

during their Antarctic expedition. However,

we know that the thickness of the glass was not increased, because window glass

recovered

from HMS Erebus in 2015 has the same thickness as that specified on Terror’s (i.e., Belzebub’s) original 1812 building contract (3).

Below, I’ll outline how I have recreated Terror’s windows for my model. Though few pictures have been

released, they appear to compare well with the recent Parks

Canada images of Terror’s stern. The great cabin on

the other side of those windows was the nerve-center of the living ship, where all

the achievements, misfortunes, and decisions of the expedition were debated,

decided, and recorded. In the coming years, it is a place where all the

expedition’s mysteries may be revealed.

References:

(1) Parry, William Edward. 1824. Journal of a Second Voyage

for the Discovery of a North-west Passage from the Atlantic to the

Pacific: Performed in the Years 1821- 22-23, in His Majesty's Ships Fury

and Hecla, Under the Orders of Captain William Edward Parry, R.N., F.R.S., and

Commander of the Expedition. London.

(2) Departure of the “Erebus” and “Terror” on the

Arctic Expedition. Illustrated London News, May 24th, 1845. Volume

6, Page 328.

(3) National Maritime Museum, ADT0010

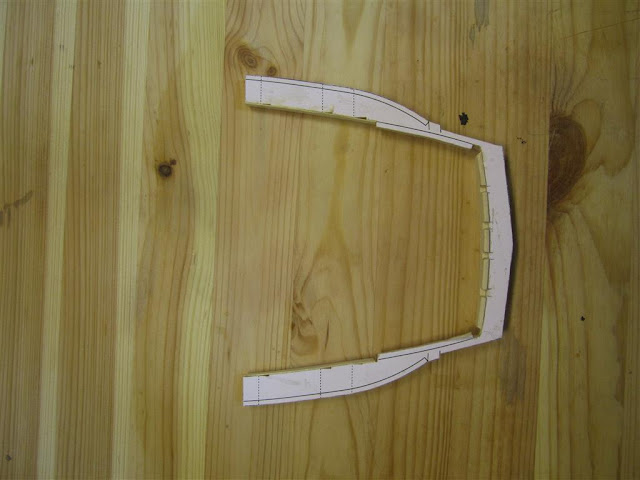

|

| Construction of the stern windows began with laser cutting the sashes from a sheet of Swiss pear. |

|

| A bevel was added to each muntin with a hand file. The filed windows are on the left, the unfinished windows are on the right. |

|

| Comparing progress to the original woodcut. |

|

| Instead of adding four individual panes, I opted to add a single simulated pane. This was achieved by carving out the backside of the windows to accept the simulated glass. |

|

| A beading line of CA was used to glue the panes in place. |

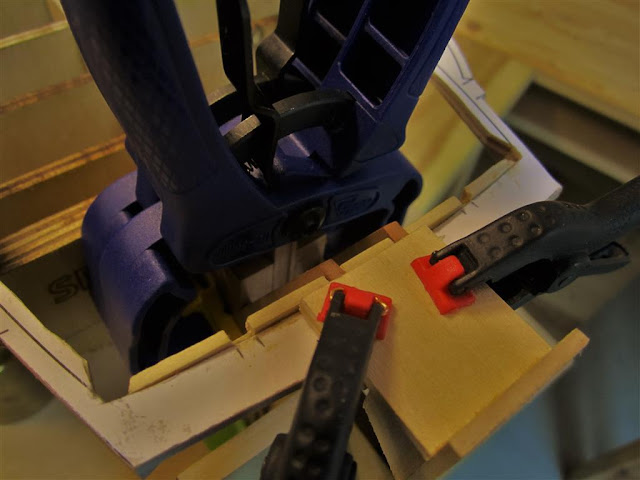

|

| Allowing the glue to dry. |

|

| A pair of finished windows compared to the woodcut. Note the double sashes in the woodcut image. |

|

| Gluing the sills to the sashes. These are not the proper configuration, but will not be visible on the finished model. |

|

| A nickle for scale. |

|

| The completed double windows. |

|

| A closeup view. |

|

| The interior panes were sanded to simulate frost (and to prevent a view into the interior of the model). |

|

| The port stern lights installed between the stern frames. |

|

| A view from the interior of the model. The imposing nature of the well can be seen here. |

|

| Approximating the view from the great cabin (as best possible). |

|

| The completed stern gallery. |

|

| Mini-Cozier surveys the pack from the comfort of his great cabin. |